Navigating through the maze of choices for windshield replacement, vehicle owners often find themselves at a crossroads, weighing the benefits of cost against quality.

Enter polyvinyl butyral (PVB), a silent yet resilient hero that stitches safety, durability, and clarity into the fabric of auto glass technology.

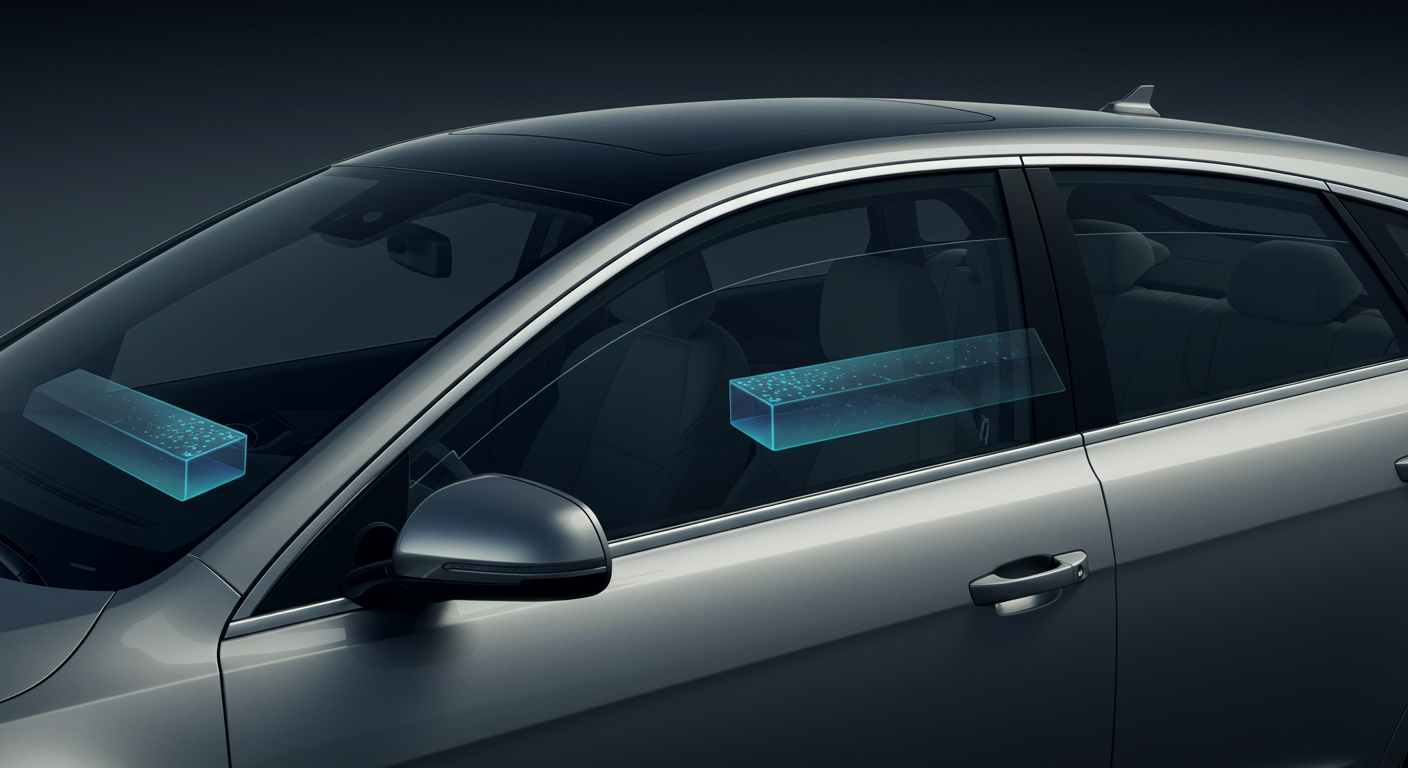

This resin, known for its robustness, transforms an ordinary piece of glass into a shield that guards against the elements, all while providing crystal-clear visibility and a layer of soundproofing that whispers comfort into the cabin of any car.

In the bustling streets of the automotive industry, where the flicker of innovation never dims, PVB stands tall as a beacon of progress.

To unravel the mysteries and untold advantages of PVB in windshield technology, keep turning the pages of this intriguing exploration.

Key Takeaways

- Polyvinyl Butyral (PVB) Is Integral to the Safety and Durability of Auto Glass, Enhancing Protection Against Impacts, UV Rays, and Weather Conditions

- PVB Laminated Windshields Offer Economic Benefits by Reducing the Frequency of Replacements and Potentially Lowering Insurance Premiums

- The Installation of a PVB Windshield Involves Precise Tools and Techniques to Maintain Vehicle Safety and Integrity

- PVB Stands as a Pillar of Sustainability in the Automotive Industry, Supporting Environmentally Friendly Practices Through Recyclability

- Selecting a Quality PVB Laminated Glass Involves Assessing Certification Marks, Clarity, and UV Protection Features to Ensure Optimal Safety and Visibility

The Basics of Polyvinyl Butyral in Windshield Technology

Within the labyrinth of innovation that characterizes the automotive industry, Polyvinyl Butyral (PVB) stands as a sentinel of safety and durability in auto glass technology.

An unsung hero, this resinous material plays a pivotal role—not just as a component, but as a guardian that fortifies the windshield against the myriad challenges it faces.

As we peel back the layers of windshield construction, understanding the essence of PVB becomes paramount.

It’s not merely about binding glass layers; it’s about transforming the windshield from a mere barrier to a bulwark that shoulders responsibilities far beyond its apparent scope.

From enhancing the durability to elevating the safety features of auto glass, PVB’s contributions are multifaceted.

The ensuing discussion illuminates how this resilient material not only repels the adversities posed by impacts and debris but also becomes central to the efficacy of safety features integral to modern vehicular design.

What Is Polyvinyl Butyral (PVB) and Its Role?

In the orchestration of windshields that stand the test of time and elements, polyvinyl butyral (PVB) commands a pivotal position. This marvel of chemistry, an unassuming yet robust resin, acts as the sinew binding layers of glass, imbuing them with strength and resilience. Such fortification not only elevates safety by minimizing injury during impacts but also contributes significantly to the soundproofing and thermal regulation within the vehicle, underscoring its indispensable role in the realm of affordable auto glass windshield replacement.

How PVB Contributes to Windshield Durability

In the symphony of materials that compose the car’s first line of defense, polyvinyl butyral (PVB) emerges as a virtuoso, orchestrating a reinforcement that significantly enhances the windshield’s ability to withstand the rigors of everyday use. Its inherent elasticity absorbs and distributes the energy from impacts, preventing the glass from shattering into dangerous shards, and by doing so, PVB extends the lifespan of windshields, making it a cornerstone in the pursuit of durability within the realm of affordable auto glass windshield replacement.

The Impact of PVB on Safety Features of Auto Glass

In the realm of automotive safety, the role of Polyvinyl Butyral (PVB) transcends mere durability, acting as an unsung hero in enhancing the protective capabilities of windshield glass. By seamlessly binding together layers of glass, PVB creates a barrier that is not only tough against the brute force of collisions but also protective against potential injury, ensuring that shards do not become airborne projectiles in the event of a crash. This laminated safety glass technology significantly elevates the safety standards of vehicles, offering peace of mind to drivers and passengers alike:

- PVB’s elasticity efficiently absorbs energy from impacts, thereby reducing the risk of glass breakage.

- The laminated layer functions as a vital component in the event of a collision, holding shattered pieces together and preventing them from causing injury.

- Its UV-blocking properties safeguard passengers from harmful ultraviolet rays, contributing to a safer and more comfortable driving experience.

Cost-Effective Windshield Repair Solutions With PVB

As we navigate the economics of vehicle maintenance, the role of Polyvinyl Butyral (PVB) in maintaining affordability in windshield replacement emerges starkly.

This section delves into the financial implications of choosing PVB laminated glass over alternatives, bringing to light not just the durability and safety advantages, but also the significant cost benefits.

A comparative analysis reveals the economic edge PVB-equipped windshields offer against their counterparts, underscoring the material’s contribution to cost-efficient fixes and reductions in the overall expenditure on auto glass repair processes.

Addressing these aspects, we unfold the layers of PVB’s pivotal role in streamlining windshield maintenance expenses without compromising on quality or safety.

PVB’s Role in Keeping Windshield Replacement Affordable

In the labyrinthine journey of maintaining a car, the choice of windshield glass emerges as a path marked by economic decisions without compromising safety or quality. Polyvinyl Butyral (PVB), a sentinel in the automotive glass industry, plays a transformative role in keeping windshield replacement and repair costs within reach for vehicle owners. By offering a durable solution that stands up to the ravages of time and nature, PVB inherently minimizes the frequency of replacements needed, thereby sculpting a landscape where quality meets affordability:

- PVB’s resilience reduces the need for frequent replacements, stretching the dollar further for car owners.

- Its capacity to hold shattered glass in place can transform a full replacement scenario into a repairable one, easing financial pressures.

- The material’s effectiveness in mitigating damage from impacts means that insurance claims can be kept to a minimum, indirectly leading to lower insurance premiums over time.

Comparison of PVB Windshields With Other Materials

In the expansive realm of auto glass technologies, Polyvinyl Butyral (PVB) laminated windshields hold a distinct advantage over their counterparts such as tempered glass, particularly in the context of cost-effectiveness and safety. Where tempered glass may shatter into countless small pellets, reducing visibility and necessitating immediate replacement, PVB’s resilience allows it to absorb and mitigate the force of impact, resulting in fewer instances of complete windshield failure. This intrinsic durability not only prolongs the windshield’s lifespan but also translates into tangible savings for the vehicle owner, establishing PVB windshields as a financially prudent option in the automotive industry.

The Cost-Saving Benefits of PVB in Repair Processes

In the intricate ballet of auto glass repair, Polyvinyl Butyral (PVB) plays a critical role in economizing the process without skimping on safety or quality. By enabling the restoration of windshields that might otherwise need complete replacement, PVB not only prolongs the life of the auto glass but also offers substantial cost savings to vehicle owners. This unique resin, by fortifying the windshield against further damage, streamlines repair processes, making it a financially savvy choice in maintaining vehicle integrity.

Enhancing Visibility and Safety Through PVB Lamination

In the intricate world of auto glass technology, polyvinyl butyral (PVB) stands as a linchpin for enhancing both visibility and safety in windshields.

By infusing clarity and resilience into the heart of windshield construction, PVB elevates the driving experience to unprecedented levels.

It’s not just about creating a barrier between the occupants and the outside world; it’s about forging a clear, unobstructed view that shields drivers from the unpredictability of the road.

The upcoming discussion sails through the myriad ways PVB refine optical quality, bolster weather, and impact resistance, and fortify driver safety, portraying a vivid tableau of its indispensable role in pushing the boundaries of what we expect from affordable auto glass windshield replacements.

How PVB Improves Optical Quality of Windshields

In the crucible of windshield technology, polyvinyl butyral (PVB) emerges as a beacon of innovation, significantly enhancing the optical quality of auto glass. By harmonizing the refractive indexes of the glass layers it bonds, PVB ensures a distortion-free view that is paramount for driver visibility. This clarity, emblematic of a commitment to safety, transforms the windshield from a mere component to an essential ally against the elements and hazards of the road, championing a clear line of sight for every journey undertaken.

The Contribution of PVB to Weather and Impact Resistance

In its role as a stalwart defender against the elements, Polyvinyl Butyral (PVB) significantly bolsters the windshield’s resistance to both weather-related wear and sudden impacts. By acting as an interlayer in laminated glass, PVB grants the windshield an extraordinary capability to withstand the pressures and thermal variations brought on by extreme temperatures, from the scorching heat of Florida’s sun to the biting cold of a frosty morning. This resilience is crucial, not just for the longevity of the windshield, but also for maintaining clear visibility and structural integrity under conditions that might compromise less fortified auto glass.

- PVB’s elasticity grants windshields an incredible resilience, enabling them to maintain form and function amid tempestuous weather conditions and thermal fluctuations.

- By curbing the impact of external pressures, PVB ensures that visibility remains unblemished, safeguarding the driver’s ability to navigate safely through diverse environmental challenges.

- The layer acts as a shield that effectively absorbs and dissipates energy, significantly lowering the risk of damage from debris, thereby safeguarding both the passengers within and the investment made in the vehicle’s maintenance.

Ensuring Driver Safety With Enhanced PVB Technology

Through the innovation of Polyvinyl Butyral (PVB) lamination, windshield technology undergoes a transformative leap in enhancing driver safety. PVB’s remarkable ability to bind glass layers into a cohesive, robust shield does more than prevent fragmentation upon impact; it actively contributes to the fortification of the vehicle’s overall safety system. Consequently, this advancement in auto glass ensures that vital safety features, such as airbag deployment, perform optimally by maintaining the windshield’s integrity during collisions, thereby offering an additional layer of protection and peace of mind for occupants.

The Environmental Benefits of Using PVB in Auto Glass

In the verdant expanse of sustainable practices within the automotive industry, polyvinyl butyral (PVB) shines as a beacon of environmental responsibility.

As society marches toward a greener tomorrow, the demand for materials that blend performance with eco-consciousness has never been more pressing.

PVB, in its silent yet impactful way, addresses this call by bolstering the eco-friendliness of auto glass manufacturing.

Its role extends beyond safety and durability, diving into the realms of recyclability and sustainable production methods.

These attributes illuminate PVB’s significance in crafting laminated glass that not only protects but also respects the planet, paving the way for discussions on its recyclability and the inherently eco-friendly characteristics that make PVB laminated glass a paragon of sustainable manufacturing within the realm of affordable auto glass windshield replacement.

PVB’s Role in Sustainable Auto Glass Manufacturing

In the vanguard of sustainable auto glass manufacturing, Polyvinyl Butyral (PVB) carries the torch, ensuring that safety and environmental stewardship walk hand in hand. PVB’s inherent recyclability transforms it into a linchpin for green initiatives within the automotive industry, allowing damaged windshields to be repurposed rather than relegated to landfills. This sustainable cycle reinforces the eco-friendly mantra that Faith Low Price Auto Glass upholds, weaving responsibility into the very fabric of auto glass replacement.

- PVB stands as a beacon of sustainability, guiding the automotive industry towards greener practices.

- Its recyclability underscores a commitment to environmental stewardship, crucial for the ethos of Faith Low Price Auto Glass.

- By promoting the reuse and recycling of auto glass, PVB garners acclaim for its role in reducing ecological footprints.

Recyclability and Eco-Friendliness of PVB Laminated Glass

In a world thirsting for sustainable solutions, Polyvinyl Butyral (PVB) infused laminated glass emerges as a harbinger of eco-friendly innovation within the automotive realm. Faith Low Price Auto Glass champions this environmentally considerate approach, endorsing PVB’s recyclability that paves the way for windshields to be reborn rather than relegated to refuse. This practice not only underscores the company’s commitment to ecological integrity but also aligns with the broader industry’s pivot towards greener, more sustainable manufacturing processes.

Installation Process of PVB Laminated Windshields

Embarking on the installation of a PVB laminated windshield marks a significant step towards reinforcing vehicle safety and visibility, while ensuring affordability in auto glass replacement.

Navigating the intricacies of this process demands not only a nuanced understanding of the materials involved but also a mastery over the specialized tools and techniques designed to achieve optimal windshield placement.

The following discourse embarks on a comprehensive exploration of the step-by-step guide to installing a PVB windshield, shedding light on the tools and techniques pivotal for securing the glass precisely and safely within the vehicle’s framework.

Step-by-Step Guide to Installing a PVB Windshield

The installation of a PVB laminated windshield begins with the meticulous removal of the old, compromised glass, ensuring that the vehicle’s frame is left unscathed and primed for the new installation. Expert technicians, armed with specialized tools, then carefully position the new PVB windshield, making certain that it aligns flawlessly with the vehicle’s contours for optimal visibility and seal. The process concludes with a thorough inspection, certifying that the windshield is securely affixed and the vehicle’s safety integrity is uncompromised, thereby upholding Faith Low Price Auto Glass’s commitment to quality and affordability.

Tools and Techniques for Optimal PVB Windshield Placement

The pivotal phase of installing a PVB laminated windshield, spearheaded by Faith Low Price Auto Glass, revolves around the precision of both tools and techniques to guarantee optimal placement. Expert technicians employ a suite of specialized tools including suction cups for secure handling, precision cutters for the custom fit, and rollers to effectively bond the PVB layer with the glass, ensuring an impeccable seal against the vehicle’s framework. This orchestration of tools and techniques safeguards the structural integrity of the windshield, promising enhanced visibility and protection for the vehicle’s occupants.

- Technicians start by meticulously removing the existing glass, preserving the vehicle’s integrity.

- Suction cups are then used to maneuver the new PVB windshield into position, ensuring a perfect alignment.

- Finally, a combination of precision cutters and rollers solidifies the bond between PVB and glass, completing the installation process.

The Future of PVB in Auto Glass Innovations

As the automotive industry steers towards the horizon of innovation, Polyvinyl Butyral (PVB) is gearing up for a transformative journey, signaling a renaissance in windshield technology.

The advent of novel PVB lamination techniques promises not only to reinforce the safety and durability of auto glass but also to elevate the overall driving experience.

This trajectory towards emerging technologies heralds a period where the role of PVB extends well beyond its conventional confines, aiming to enhance driver visibility, and interaction with the vehicle’s environment.

PVB’s evolution is set to redefine the parameters of what makes auto glass not just a protective barrier, but a dynamic element that integrates seamlessly with the advancing needs of drivers and passengers.

Thus, the journey of PVB in the automotive spectrum is shifting gears, preparing to drive future innovations in windshield technology that align with both safety mandates and the imperatives of enhanced driver experience.

Emerging Technologies in PVB Lamination for Windshields

As technology marches forward, Polyvinyl Butyral stands on the cusp of revolutionary change in auto glass lamination. The introduction of smart PVB layers, capable of morphing in response to environmental stimuli, promises to elevate windshield functionality, offering drivers enhanced visibility and protection against elements. This leap in innovation not only signifies a brighter horizon for the safety and efficiency of windshield replacement but also reaffirms Faith Low Price Auto Glass’s commitment to affordable, cutting-edge automotive solutions.

The Evolving Role of PVB in Enhancing Driver Experience

Polyvinyl Butyral (PVB) is poised to revolutionize the interaction between drivers and their vehicles. Its evolving role in windshield technology not only prioritizes safety but is also instrumental in crafting an enriched driving experience: by ensuring optical clarity and offering protection against environmental factors, PVB is expanding the conventional boundaries of automotive glass. This transition highlights PVB’s potential to evolve from a mere safety layer into a dynamic component that significantly enhances visibility and comfort for drivers.

- PVB’s enhanced optical properties ensure unparalleled clarity, eliminating distortions to maintain a crystal-clear view of the road.

- Advancements in PVB technology promise increased resilience against external pressures, safeguarding the structural integrity of windshields.

- Through its capacity to absorb and filter ultraviolet and infrasound, PVB contributes to a more serene and comfortable driving environment, marking a significant leap towards enhancing driver experience.

Choosing the Right PVB Windshield for Your Vehicle

Embarking on the quest for the perfect Polyvinyl Butyral (PVB) windshield encompasses more than a simple act of replacement; it is a calculated decision aimed at bolstering vehicular safety and maintaining affordability.

In this intricate landscape, selecting the right PVB windshield demands a nuanced understanding of various aspects that contribute to its overall efficacy and cost-effectiveness.

This segment guides vehicle owners through the critical terrain of identifying high-quality PVB laminated glass, laying out essential tips for navigating through the myriad of affordable PVB windshield options.

With safety, durability, and financial considerations at the forefront, making an informed choice becomes not just a preference but a necessity for every discerning car owner.

Factors to Consider When Selecting a PVB Windshield

In the arena of choosing the appropriate Polyvinyl Butyral (PVB) windshield, discerning vehicle owners consider compatibility with the car’s make and model, the quality and reputation of the manufacturer, and the rigor of the safety and durability standards that the glass meets. The gravitas of this selection process crystallizes around securing a windshield that not only promises to safeguard the occupants from impacts and ultraviolet radiation but also integrates seamlessly with the vehicle’s original design and safety mechanisms, ensuring both aesthetic coherence and functional superiority.

How to Identify High-Quality PVB Laminated Glass

To discern high-quality Polyvinyl Butyral (PVB) laminated glass, a keen eye on certification marks from reputable safety standards organizations is imperative. These symbols, often etched subtly onto the glass, whisper tales of rigorous testing and adherence to stringent safety and durability criteria: a guarantee of protection and longevity. Thus, opting for PVB windshields adorned with these marks of excellence becomes a beacon for those seeking unwavering quality and reliability in their vehicular safeguarding.

| Feature | Significance | Identification |

|---|---|---|

| Certification Marks | Indicates adherence to safety and quality standards | Easily found etched onto the glass |

| Clarity | Essential for unobstructed visibility | Visual inspection for distortions or blurs |

| UV Protection | Shields occupants from harmful ultraviolet rays | Specifications provided by the manufacturer |

Tips for Finding Affordable PVB Windshield Options

In the quest for affordable PVB windshield options, savvy car owners lean towards seeking quotations from multiple vendors and exploring insurance coverage benefits meticulously: a strategy that unveils the spectrum of pricing while potentially unlocking insurance perks dedicated to safety enhancements like PVB laminated glass. Recognizing that varying vendors offer a kaleidoscope of deals and warranties, the diligent comparison not only ensures a competitive price but also guarantees that the chosen windshield deployment does not compromise on quality or safety standards.

| Strategy | Benefits | Expected Outcome |

|---|---|---|

| Quotations from Multiple Vendors | Unveils a spectrum of pricing, highlighting cost-effective options | Identification of the most affordable PVB windshield replacement offer without sacrificing quality |

| Exploring Insurance Coverage | Potentially unlocks insurance benefits for safety enhancements | Reduces out-of-pocket expenses while ensuring adherence to safety standards |

Conclusion

Understanding the role of Polyvinyl Butyral (PVB) in affordable auto glass windshield replacement highlights its pivotal contribution to vehicle safety, durability, and cost-efficiency.

PVB acts as the crucial intermediary that binds glass layers, enhancing impact resistance, and ensuring the windshield integrity during collisions.

This not only elevates safety standards by preventing shards from causing injury but also contributes to UV protection and thermal regulation, enhancing the driving experience.

Moreover, PVB’s inherent durability reduces the frequency of replacements needed, thus making windshield maintenance more cost-effective for vehicle owners.

The recyclability of PVB further underscores its role in promoting environmentally sustainable manufacturing processes.

Given PVB’s significant benefits in enhancing optical quality, resisting weather and impacts, and its crucial contribution to affordable repair solutions, it is clear that Polyvinyl Butyral stands at the forefront of evolving auto glass technology, ensuring safety, sustainability, and affordability.

Leave a Comment

You must be logged in to post a comment.